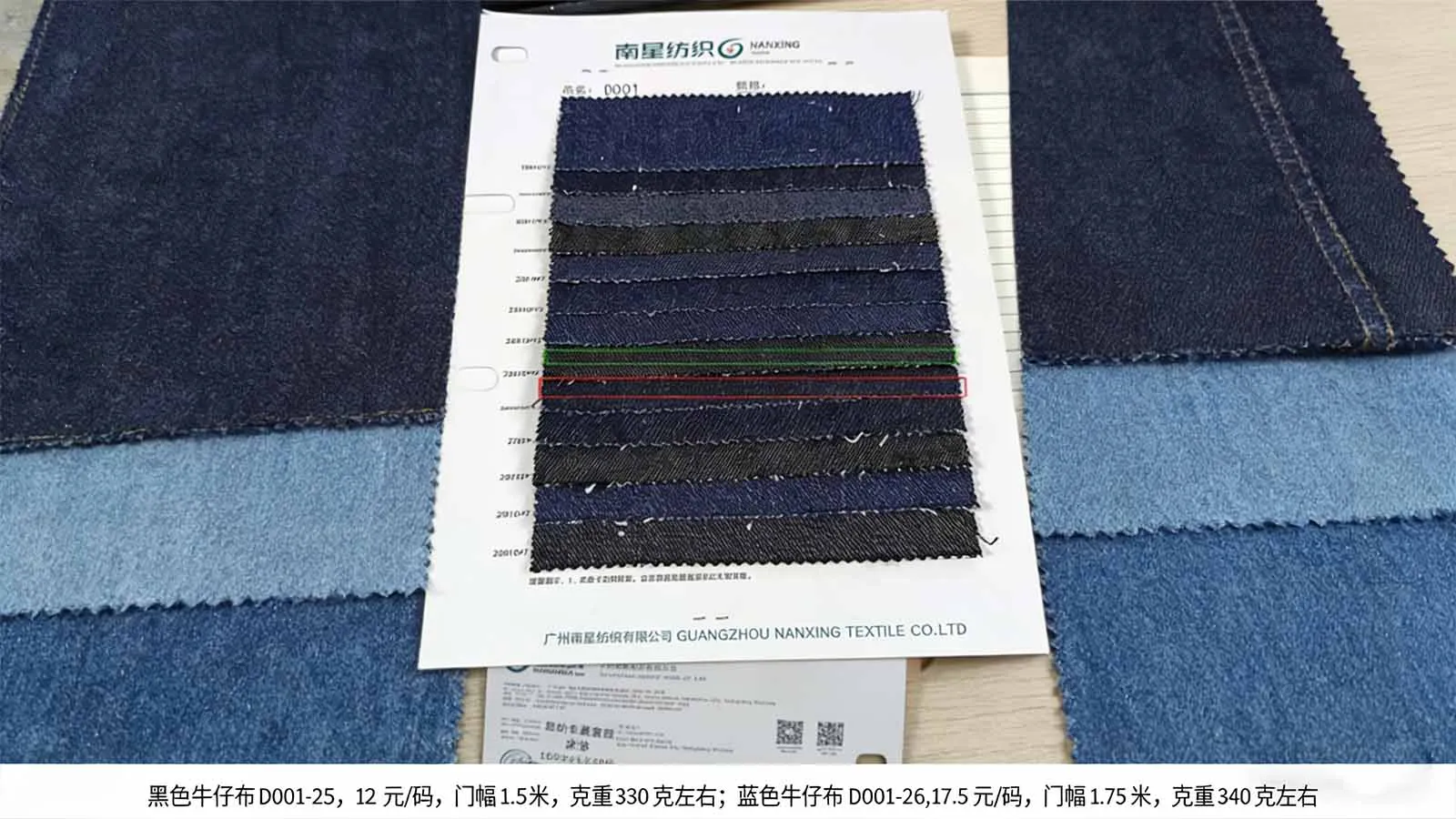

Gahumi successfully completed the production of 300 custom denim bags for Dalian University of Technology, delivering the entire order within the agreed-upon timeframe. The project was marked by exceptional quality control, ensuring that every bag met the university's stringent specifications for material, design, and craftsmanship. The client was highly satisfied with the durability, aesthetic appeal, and functional design of the bags, which perfectly captured their brand identity. Our ability to manage complex requirements, execute specialized manufacturing processes, and maintain a strict delivery schedule underscored Gahumi's commitment to excellence and client satisfaction. This achievement further solidified Gahumi’s reputation as a trusted OEM/ODM partner for custom textile products, capable of handling intricate institutional demands with precision.

🚩About the Customer

Dalian University of Technology (DUT), abbreviated as 'DUT,' is located in Dalian, Liaoning Province. It is a national key university directly under the Ministry of Education, jointly supported by the Ministry of Education of the People's Republic of China and the People's Government of Liaoning Province, with participation from the People's Governments of Dalian and Panjin. It is a centrally administered university, and a key university under the national '211 Project' and '985 Project,' as well as a Class A university under the 'Double First Class' initiative.

🚩About Gahumi

Founded in 1994, Gahumi is a comprehensive fabric-printing enterprise integrated with product R&D, design, manufacture and sales. We offer a full line of fabric-printing products, including towels, golf towels, flags, advertising T-shirts, sports items, fans’ scarves, hats & caps, and other election accessories, etc.

Based on 31 years of manufacturing experience, we have been exporting products to the US, Europe, East Asia, Africa, and the Middle East, and have established long-term partnerships with companies around the world.

With over 300 highly qualified employees and 3 manufacturing facilities covering a total area of 5,000 square meters (including a raw material center, sewing center, fully automatic printing center, and assembling center), our clients benefit from lower manufacturing costs and timely mass production for market launch.

The Solution

Display finished sample T - shirts of different techniques to enable customers to make intuitive comparisons.

FOR CUSTOM YOUR BRAND

Tshirt

Tshirt

Custom Hoodie & Sweat

Custom Hoodie & Sweat

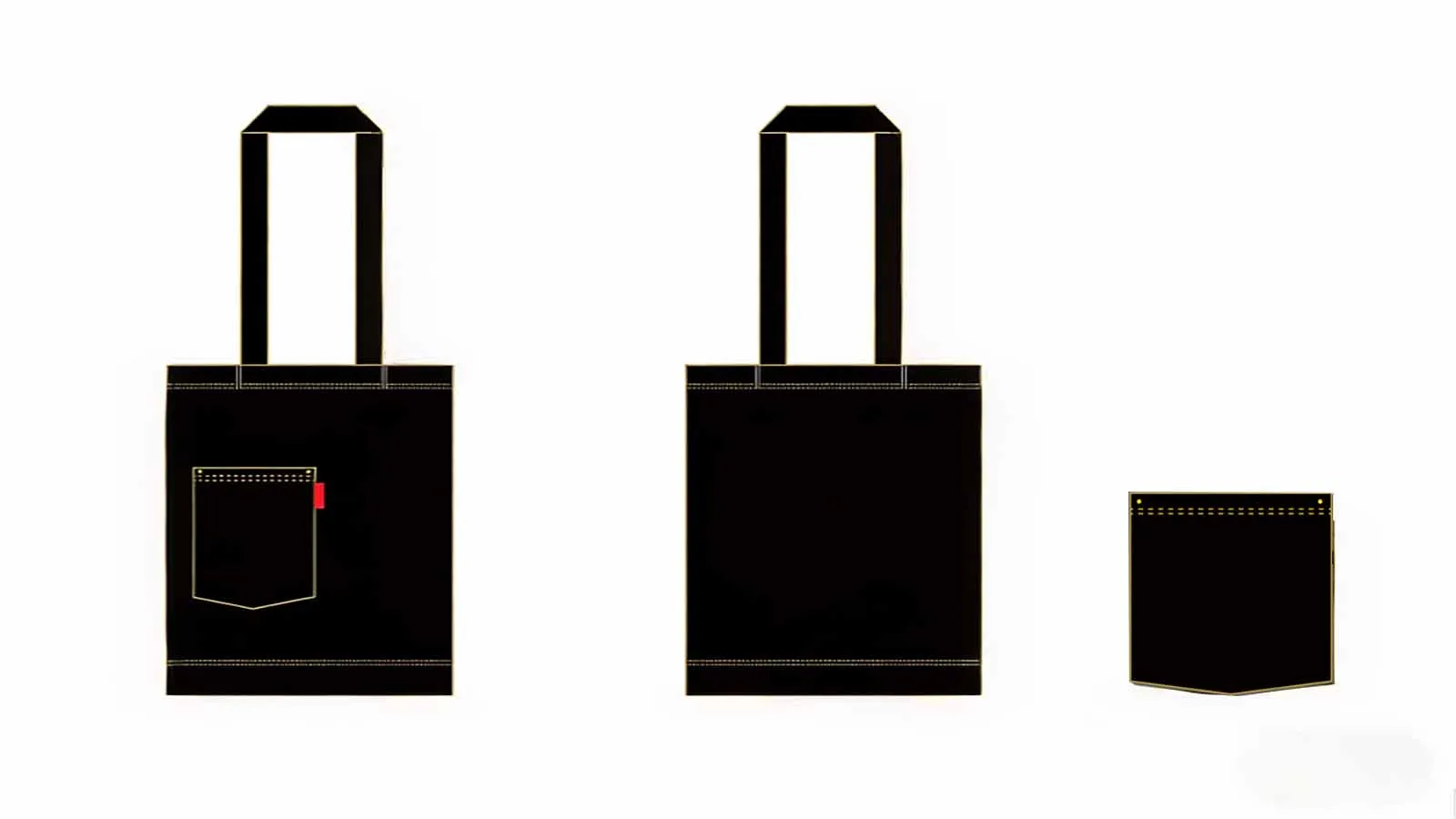

Custom Bags

Custom Bags

Flag

Flag

Towel

Towel

Custom Scarf

Custom Scarf

Cap

Cap